Innovation in manufacturing is no longer just about making parts faster. It is about making them smarter, lighter, stronger, and scalable without sacrificing precision. Ceramic Injection Molding, often shortened to CIM, has quietly become one of the most powerful technologies enabling this shift. By combining advanced ceramics with injection molding techniques and demonstrating why injection molding is ideal for ceramic production, CIM allows manufacturers to produce complex, high-performance components that were once impractical or impossible to make at scale. This process is redefining how engineers think about design, strength, and efficiency across multiple industries.

From Powder to Precision: How the Process Works

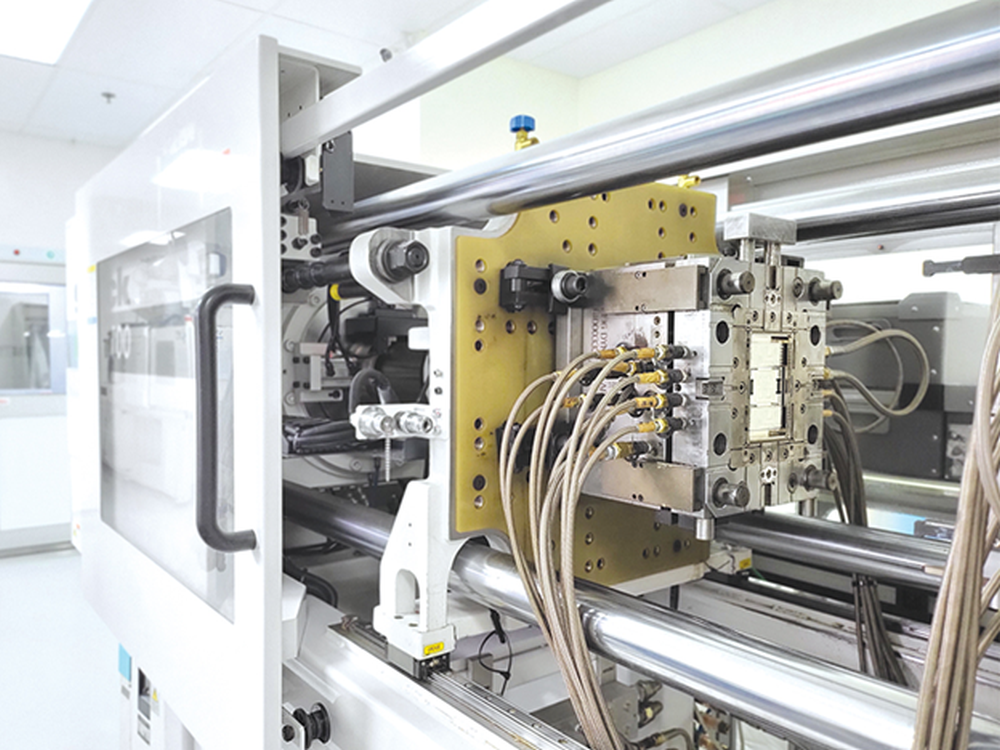

Ceramic Injection Molding starts with a simple but clever idea. Fine ceramic powders are blended with a temporary binder to create a moldable material that flows like plastic when heated. This mixture is injected into a mold, forming parts with intricate shapes and tight tolerances.

Once molded, the binder is carefully removed, and the remaining ceramic structure is sintered at very high temperatures. During sintering, the ceramic particles fuse together, creating a dense, solid component with exceptional mechanical properties. The final result is a part that combines precision geometry with the inherent advantages of advanced ceramics.

This controlled, step-by-step process is what allows CIM to deliver consistency and accuracy even when producing thousands or millions of identical components.

Complex Shapes Without Compromise

One of the standout benefits of Ceramic Injection Molding is its ability to handle complexity without driving up costs. Traditional ceramic manufacturing methods often struggle with thin walls, undercuts, or internal features. CIM handles these challenges with ease.

Designers can create parts with fine details, smooth surfaces, and integrated features that reduce the need for assembly. This opens the door to more compact designs and improved performance. Internal channels, delicate structures, and precise tolerances can all be achieved in a single molding step.

Fun fact: Some ceramic injection molded parts are so precise that they are used in applications where even microscopic imperfections could cause failure.

Lightweight Strength That Redefines Performance

Ceramics are known for being hard, heat-resistant, and chemically stable. When shaped through CIM, these properties are paired with lightweight designs that outperform many metal alternatives.

The strength-to-weight ratio of ceramic components makes them ideal for demanding environments. They can withstand extreme temperatures, resist corrosion, and maintain structural integrity under stress. At the same time, their lower weight helps improve efficiency and reduce overall system load.

This combination is especially valuable in applications where performance margins are tight and reliability is non-negotiable. Lighter components can improve energy efficiency, reduce wear on surrounding parts, and extend product lifespan.

Fun fact: Advanced ceramics can retain their strength at temperatures where some metals begin to soften or deform.

Scaling Innovation Without Sacrificing Quality

Scaling production often introduces variability. CIM stands out because it maintains consistency even as volumes increase. Once the molding parameters are optimized, each cycle produces parts that closely match the last.

Near-net-shape manufacturing plays a major role here. Parts emerge from the mold close to their final dimensions, which minimizes secondary machining. Less post-processing means fewer opportunities for errors and reduced material waste.

This efficiency is not just about speed. It allows manufacturers to bring innovative designs to market faster while maintaining high quality standards. Scaling no longer forces a trade-off between creativity and reliability.

Efficiency That Supports Sustainability

Ceramic Injection Molding also aligns well with modern sustainability goals. Because the process uses material efficiently, there is less scrap compared to traditional machining. Unused feedstock can often be recycled back into production, reducing waste.

Energy use is optimized by combining multiple shaping steps into one streamlined process. Fewer machining operations mean lower energy consumption and shorter production cycles. Over time, these efficiencies contribute to a smaller environmental footprint.

Fun fact: Near-net-shape manufacturing can reduce material waste by more than half compared to conventional subtractive methods.

Applications That Keep Expanding

CIM is already used in fields that demand precision, durability, and miniaturization. Medical components benefit from biocompatibility and wear resistance. Electronics rely on ceramics for thermal insulation and electrical stability. High-performance machinery uses ceramic parts to handle friction, heat, and chemical exposure.

As material science continues to advance, new ceramic formulations are expanding what CIM can achieve. This keeps pushing the technology into new applications where lightweight strength and complex geometry are essential.

The Road Ahead for Ceramic Injection Molding

While Ceramic Injection Molding requires expertise and careful process control, its advantages far outweigh the challenges. The ability to produce intricate, high-strength components at scale makes it a cornerstone of modern manufacturing innovation.

As industries continue to demand smarter designs, better performance, and sustainable production methods, CIM stands as a technology that delivers on all fronts. It is not just a manufacturing technique. It is a tool that enables engineers to rethink what is possible, turning bold ideas into reliable, real-world components.